Previous

Next

Laser Cutting

We have CNC laser cutting capabilities for high precision parts and prototypes that require a higher level of detail.

Waterjet cutting

We have waterjet cutting capabilities that are useful for cutting very thick sheet metal with a very high quality finish.

Plasma Cutting

We offer CNC plasma cutting services suitable for both large scale and one-off custom fabrication projects.

Assembly

We offer sheet metal assembly services using a variety of techniques including welding and riveting to help streamline production processes.

Sheet Metal Bending

Bending is a common sheet metal forming process used to shape steel, stainless steel and aluminum parts after cutting.

Enclosures

Sheet metal fabrication provides a cost-effective, reliable, and efficient solution for producing custom enclosures.

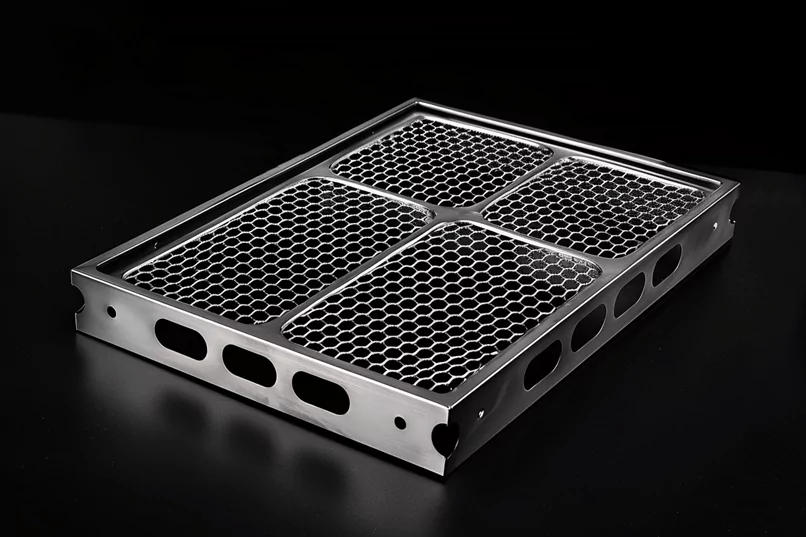

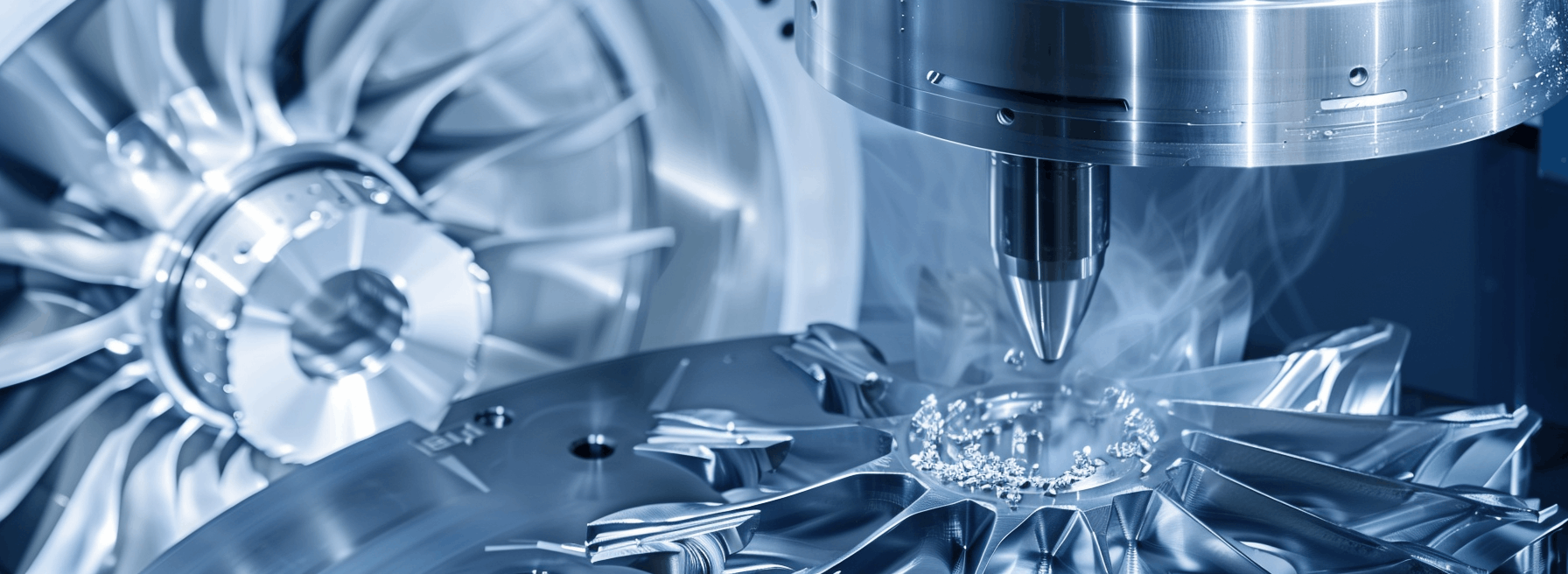

Our Services

Our Custom Sheet Metal Work Services

LRD offers prototyping and sheet metal fabrication services for the production of custom sheet metal parts, including intricate, low-volume prototypes and extensive, high-volume runs. Our clients have access to a broad selection of materials and fabrication processes. Our domestic sheet metal fabricators and a team of knowledgeable engineers ensure that each part is manufactured to exact specifications and quality standards.

Need help?

Call us for more information or business inquiry.

+86 18923709879

Wind Farms in Wales

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Wind energy at Monaco

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Jakarta Airport International

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

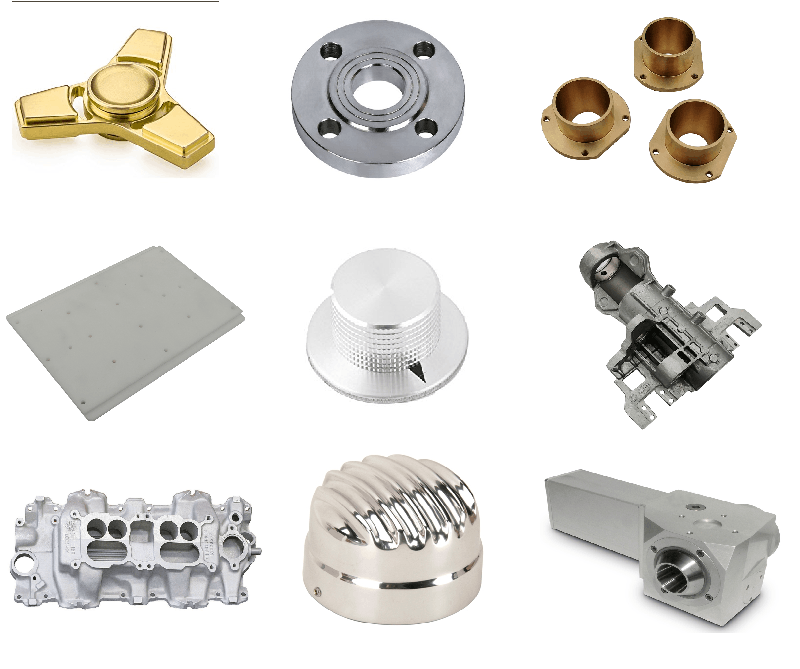

Sheet Metal Parts Made by LRD Prototyping

Previous image

Next image

Start production today.

Make on-demand manufacturing easier and faster.

Our Sheet Metal Processes

Learn about the benefits of different sheet metal techniques and find the best parts for your project.

| Process | Techniques | Precision | Applications | Material Thickness (MT) | Lead Time |

Cutting | Laser cutting, Plasma cutting | +/- 0.1mm | Stock material cutting Cutting of external shapes Secondary cutting Cutting lines Cutting irregular holes | 6 mm or less | 1-2 days |

Bending | Bending |

Single bend: | Forming, pressing lines, imprinting characters, riveting of electrostatic guide rails, pressing grounding symbols, hole punching, pressing flat, pressing triangular reinforcements, and more. | The smallest bend radius should be at least equal to the sheet thickness. | 1-2 days |

Welding | Tig Welding, MIG welding, MAG welding, CO2 welding | +/- 0.2mm | For aircraft fuselages and engine components. In car bodies, exhaust systems, and chassis. In creating components for power generation and distribution systems. | As low as 0.6 mm | 1-2 days |

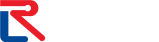

Materials for Custom Sheet Metal Parts

Metals

We offer an extensive selection of high-quality metal materials for different applications.

| Aluminum | Stainless Steel | Steel |

| Copper | Brass | Bronze |

| Titanium | Zinc |

Plastics

We also provide an impressive assortment of plastic materials designed to fulfill diverse manufacturing need.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

Sheet Metal Tolerances

Our sheet metal shops follow ISO 13485 standards to deliver consistent quality. For anything else, please tell us on the design schematics or contact our engineers.

Dimension Detail | Metric Units | Imperial Units |

| Edge to edge, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Edge to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Hole to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

| Bend to edge / hole, single surface | +/- 0.254 mm | +/- 0.010 in. |

| Edge to feature, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

| Over formed part, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Sheet Metal Finishes

Choose from our sheet metal finishes to make it last longer and look better. If you don’t see what you want on our quote page, just choose “Other” and tell us what you need.

| Applicable Materials | Colour | Description | |

Bead Blasting | All metals | Uniform matte of raw material colour | Bead blasting is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. |

Powder Coating | All metals | Black, white | Powder coating is typically used because it has a longer lasting, tougher finish than painting. |

Anodizing | All metals | Clear, black, grey, red, blue, gold | Anodising is used to increase surface hardness, wear resistance and durability of metals such as Aluminium. |

Sheet Metal FAQ

Sheet metal tolerances are the acceptable deviations for sheet metal parts. They ensure accurate and consistent installation and integration. ISO 2768-mk is used to control the geometry and size of sheet metal parts. The following shows you seven tolerance standards for linear and angular dimensions, flatness and straightness, cylindricity, and circularity.

LRD Prototyping offers a range of services including cutting, bending, punching, welding, and assembling. Our machinery ensures precision and high-quality finishes.

K factor is the ratio of neutral axis to material thickness. It changes with different materials.

Every aspect of sheet metal fabrication costs money. This includes the design, prototype, finishing processes, and materials.

LRD prototyping can make small or large production runs, from one prototype to mass production, with no minimum order quantity.

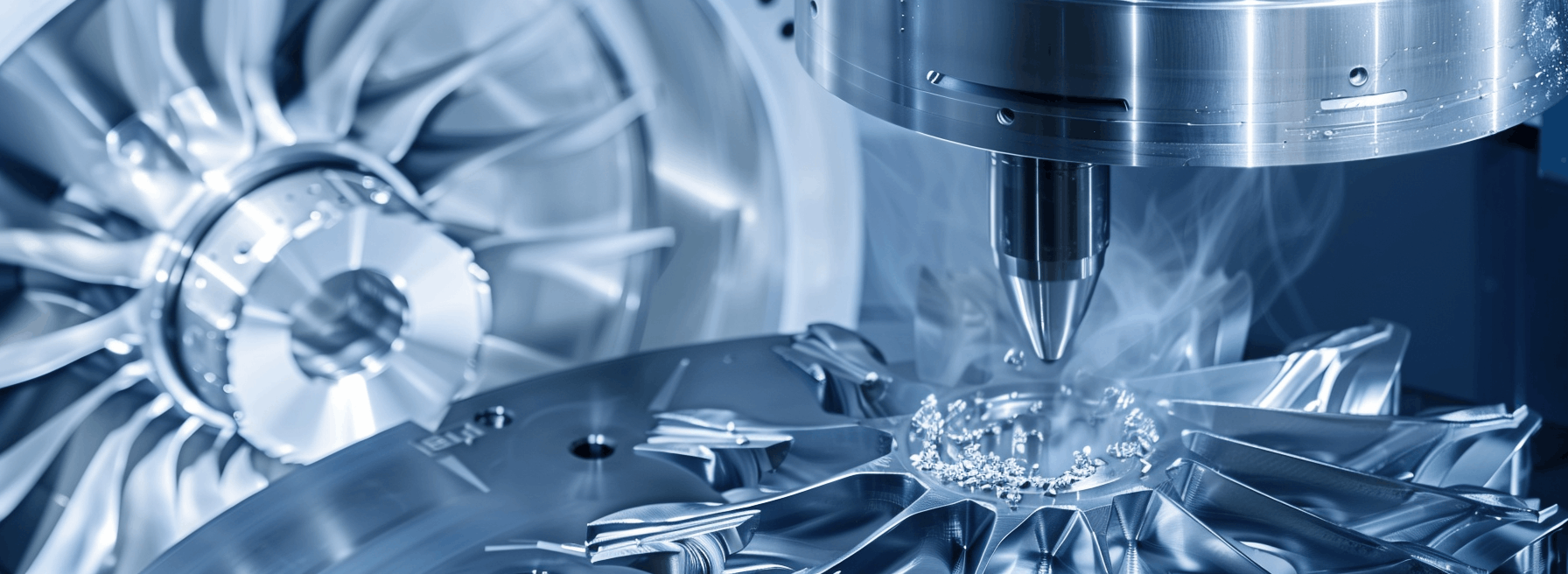

Sheet Metal Work Overview

What’s Sheet Metal Fabrication?

Sheet metal fabrication is a key process in manufacturing. It involves shaping thin metal sheets into metal components. This technique produces essential items such as enclosures, brackets, and chassis. It ensures top-quality, reliable end-use products. RapidDirect industrial sheet metal services excel in transforming metal into high-performance parts.

What Are the Advantages of Sheet Metal Fabrication?

Sheet metal fabrication is an ideal process for both prototype and large-scale production of metal components. Advanced technologies allow for high-precision cutting and forming, ensuring consistent quality. Metal components are robust and long-lasting, suitable for demanding environments. Efficient use of materials and the ability to scale production up or down make it a cost-effective solution. Various finishing techniques, such as powder coating, provide aesthetic flexibility and additional protection.

What are the applications of sheet metal?

Sheet metal is used in many different ways. It is often used to make parts for electronics, computers, and other machines.

Rapid prototyping and on-demand production for a variety of industries.

01.

Automotive

02.

MedicalDevices

02.MedicalDevices

On-demand manufacturing. Rapid prototyping to mass production of medical products.

Learn more 03.

Robotics

03. Robotics

Maximize efficiency by ensuring precise, consistent, and rapid part quality.

Learn more 04.

Communication

04.Communication

Empower your team to innovate more quickly, thereby maximizing their performance.

Learn more 05.

Aerospace

05. Aerospace

Our goal is to provide efficient production and faster design-to-delivery times.

Learn more 06.

Electronics

Related Article

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

Previous image

Next image