Previous

Next

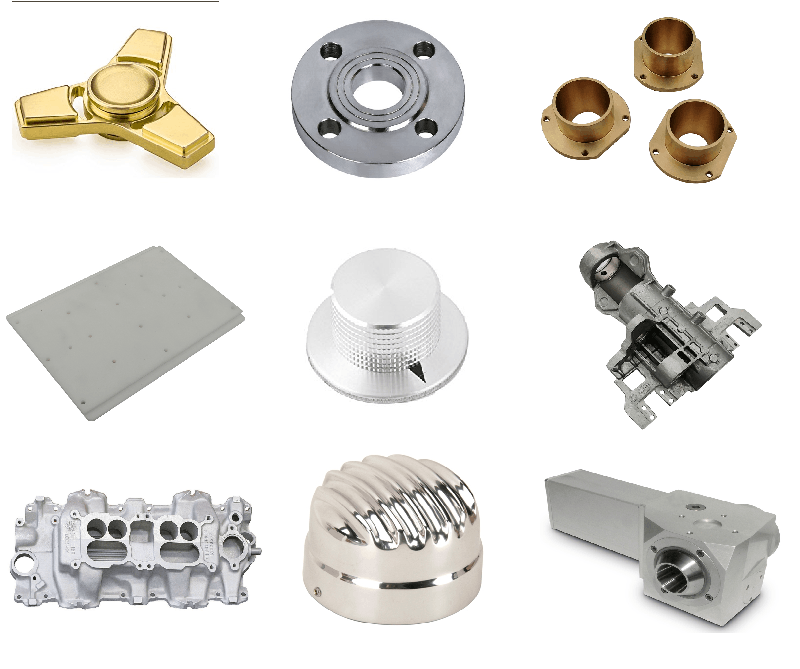

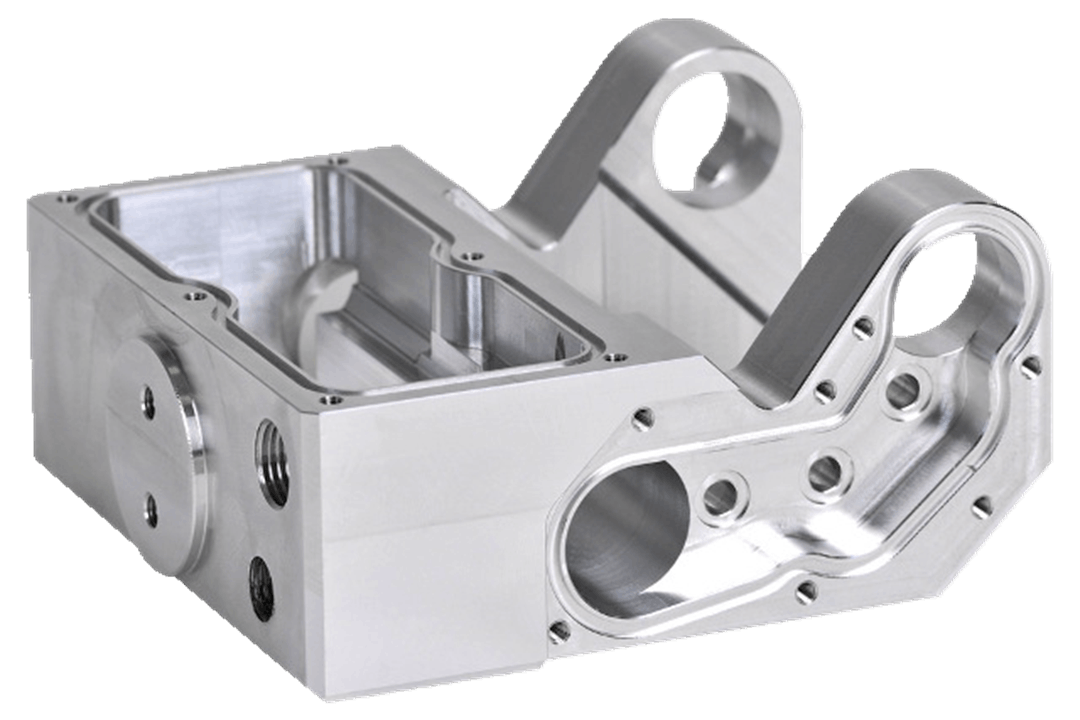

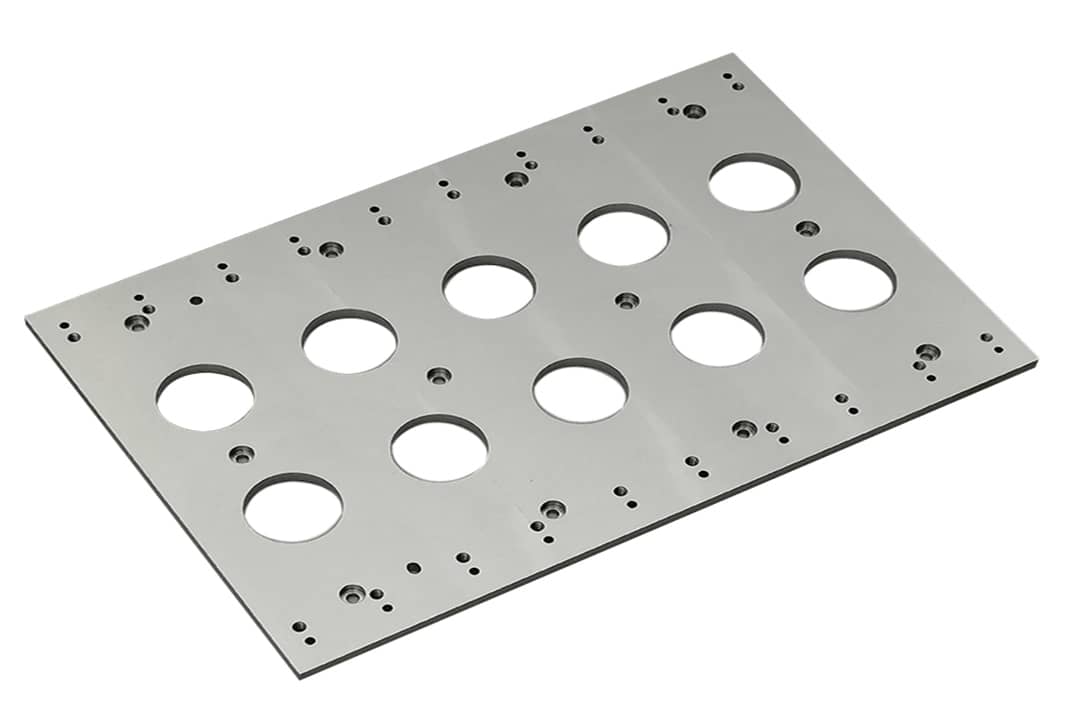

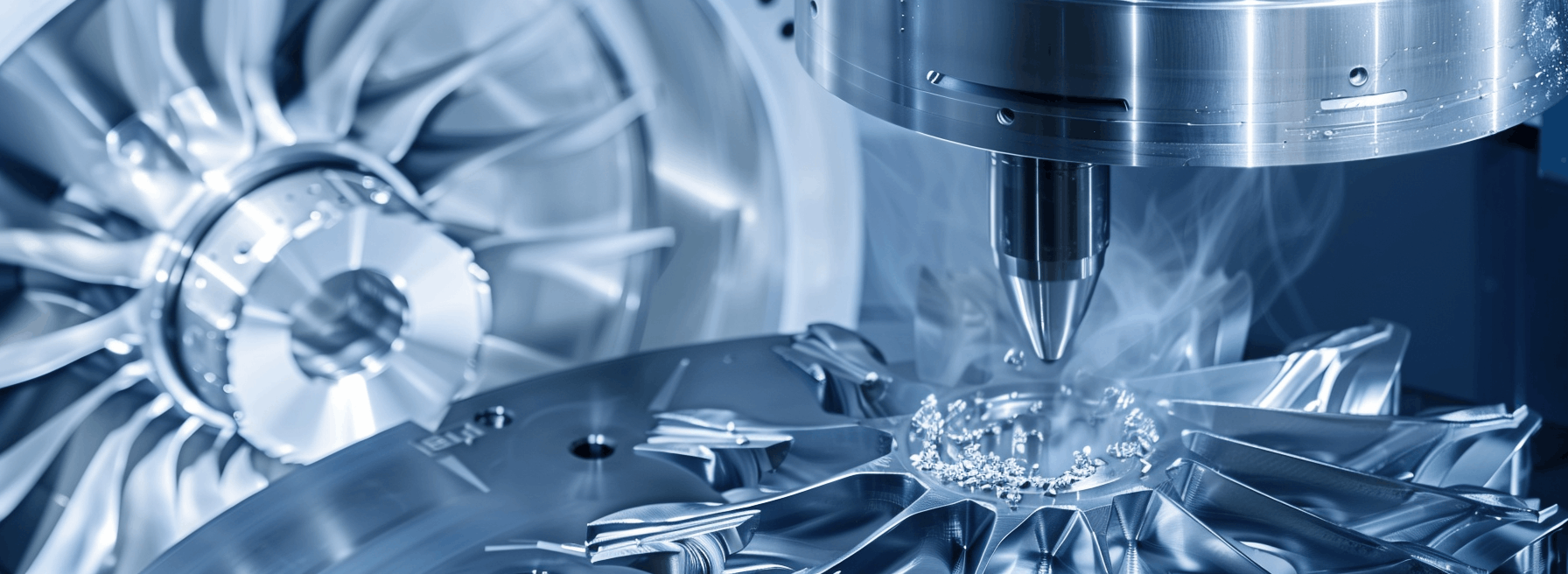

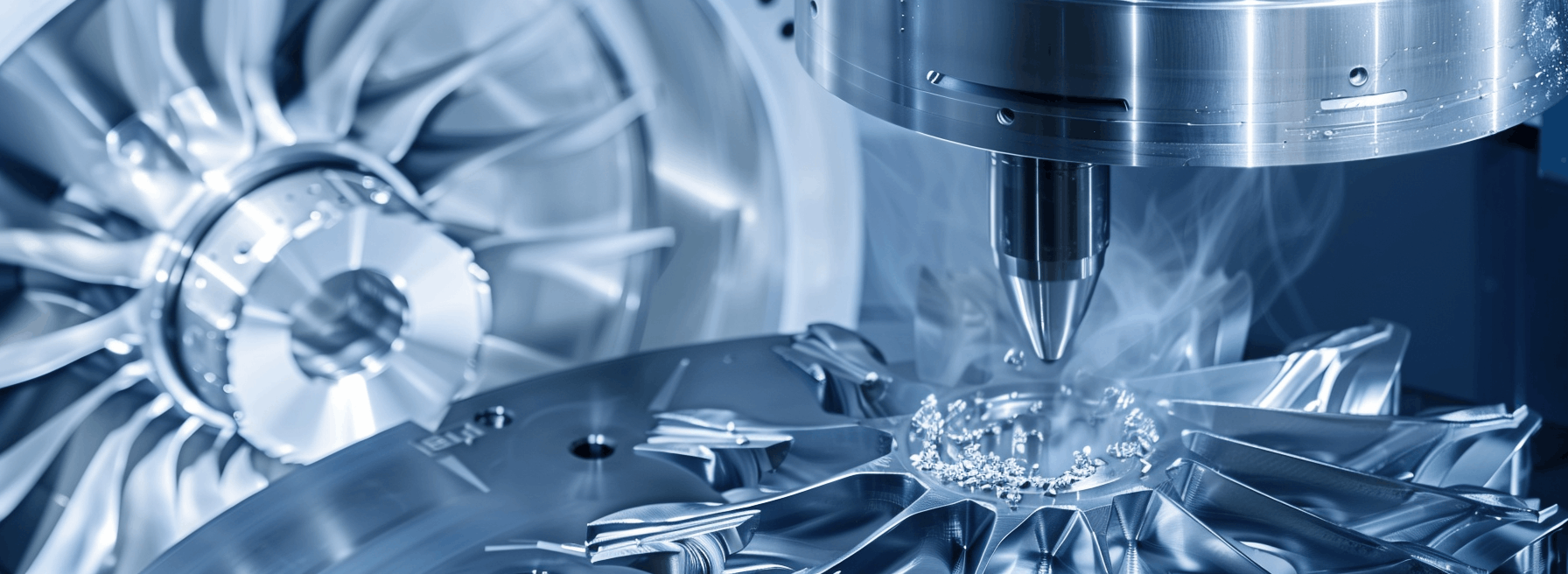

CNC Milling

Our 3, 4, and 5-axis machining capabilities allow us to handle simple and complex geometries with precision, maintaining dimensions to tolerances as tight as 0.002”.

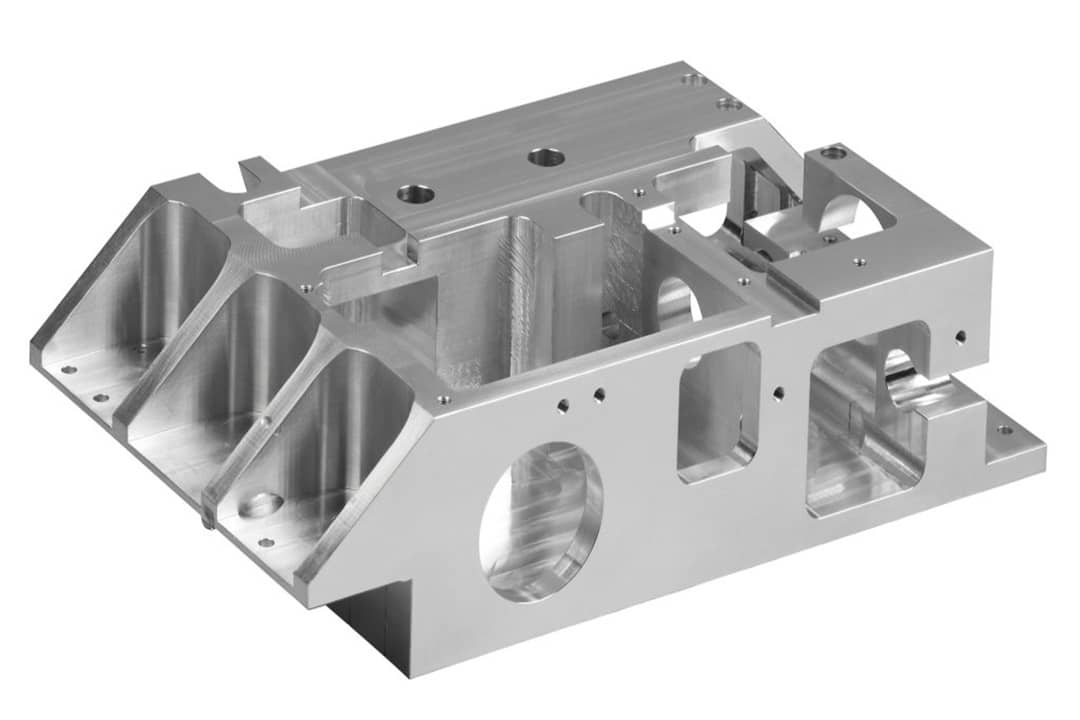

CNC Turning

Our CNC turning capabilities enable us to produce custom precision threads, deep holes, and intricate cylinder and round shapes of any type.

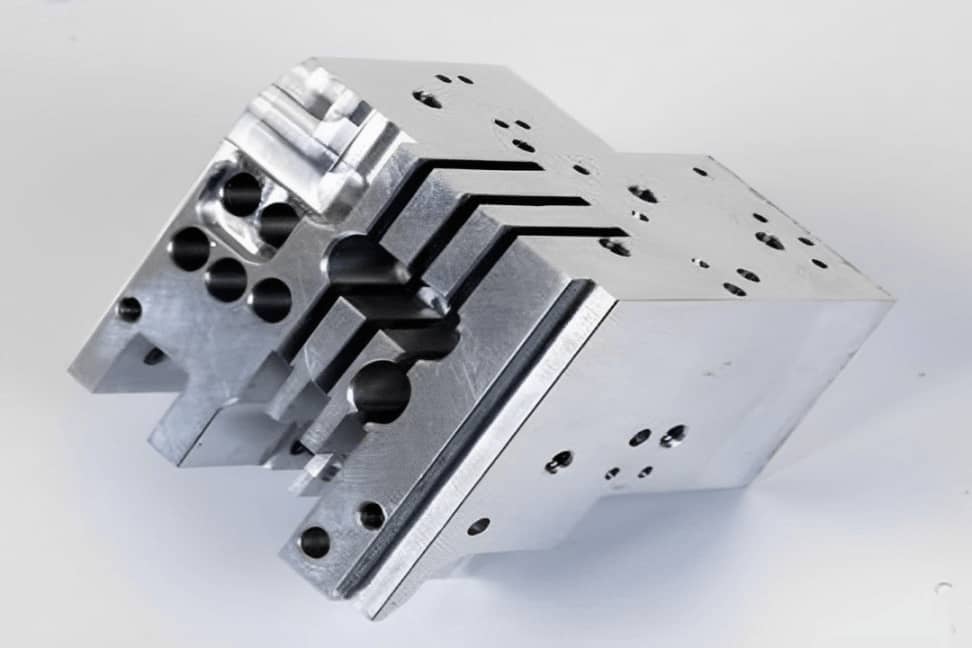

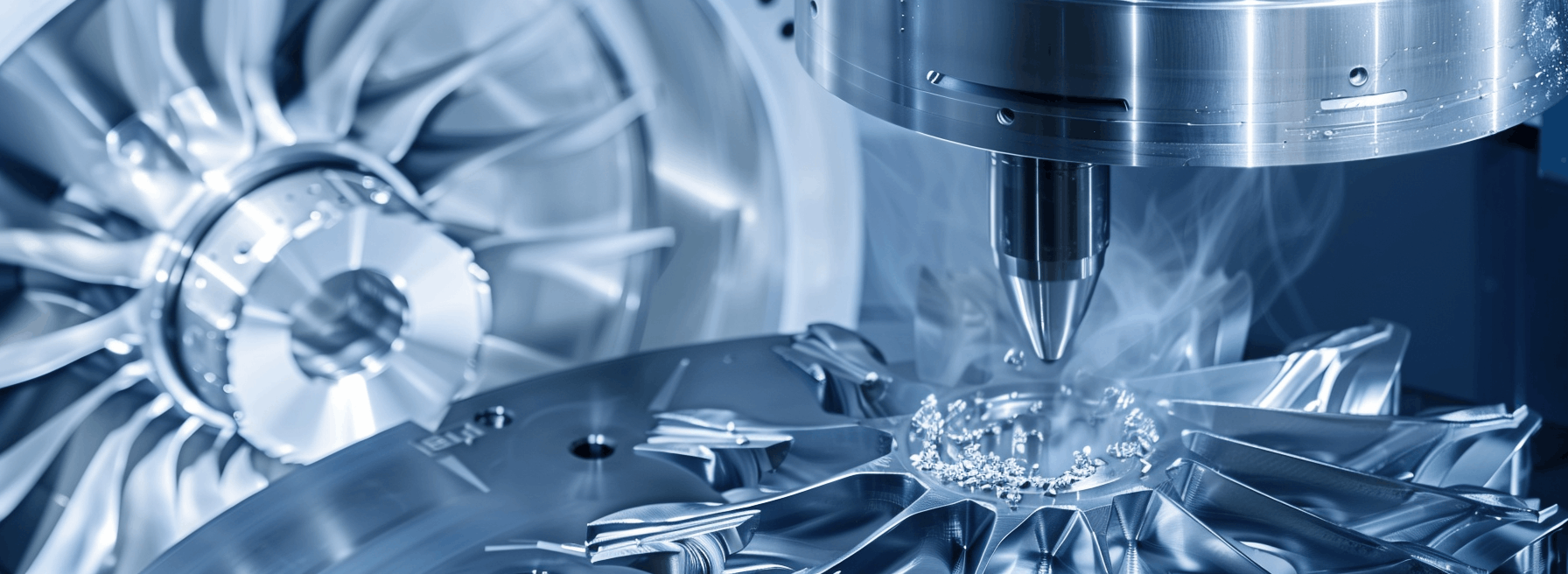

Precison Machining

Our company offers superior-quality precision CNC machining services for prototypes and production parts. We provide our clients with advanced manufacturing solutions at competitive rates and with short lead times.

Our Services

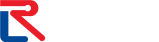

Our Custom CNC Machining Services

Our custom CNC machining services are ideal for engineers and industrial designers seeking high-speed, high-precision parts. At LRD Prototyping, we offer CNC services for rapid prototyping and low-volume production. With over 150 high-tech machines and quality control at every stage, we make the best components for you.

Need help?

Call us for more information or business inquiry.

+86 189 2370 9879

Wind Farms in Wales

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Wind energy at Monaco

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Jakarta Airport International

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Custom CNC Machining Parts

Previous image

Next image

Start production today.

Make on-demand manufacturing easier and faster.

Precision Machining Tolerance

At LRD Prototyping, tolerances are controlled to ISO-2678 Fine (F) for metals and Medium (M) for plastics as standard. Tighter tolerances available on request.

| Operation Type | Typical Tolerance (mm) | Best Possible Tolerance (mm) | Notes |

| EDM (Electrical Discharge Machining) | ±0.015 | ±0.005 | Tolerance can be affected by electrode wear. |

| Grinding | ±0.005 | ±0.001 | Surface finish is typically smoother with grinding. |

| CNC Turning | ±0.025 | ±0.010 | Finish can impact tolerance. |

| CNC Milling | ±0.025 | ±0.005 | Precision can vary based on tool type and material. |

Materials for Custom CNC Machining Parts

Metals

We offer an extensive selection of high-quality metal materials for different applications.

| Aluminum | Stainless Steel | Steel |

| Copper | Brass | Bronze |

| Titanium | Zinc |

Plastics

We also provide an impressive assortment of plastic materials designed to fulfill diverse manufacturing need.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

CNC Machining FAQ

CNC prototyping uses computer-controlled machines to make precise prototypes from digital designs. These machines carve out shapes from materials like plastic, metal, or wood based on the design. Starting with a digital model, the CNC machine follows exact instructions to create the prototype, ensuring high accuracy and intricate details.

Unlike traditional prototyping methods, CNC rapid prototyping allows for iterations within days. This process speeds up product development by allowing quick testing and adjustments before making the final product. Industries like automotive, aerospace, medical and electronics use CNC prototyping to test concepts, refine designs, and ensure quality before mass production. It’s a vital step that brings ideas to life, improving products and meeting high standards.

CNC parts could cost from as low as $100, or as high as $1000 or more. The price depends on the material, tolerance, machining hours, geometrical complexity, part size or quantity.

The two primary CNC machining processes are CNC turning and CNC milling.

- CNC milling shapes out of a metal or plastic material blank that is usually flat, holding dimensions to tolerances as tight as 0.002”.

- CNC turning rotates the part when machining the desired shape, which results in cylindrical parts.

Many industries rely on CNC machining for high-precision parts and prototypes, including:

- aerospace & defense

- automotive

- electronics

- robotics

- medical

- oil & gas

For features left unspecified, standard tolerances are used. The standard machining tolerance is ISO 2768 Fine (F) for metals and Medium (M) for plastics. Tighter tolerances are available on request.

CNC Machining Overview

What is CNC Machining?

CNC Machining, or Computer Numerical Control Machining, is a manufacturing technique where computer-controlled devices are used to remove layers from a material, creating detailed parts or components. Through a combination of tooling and precise machine movement, it produces parts to exact specifications. The CNC machine reads these commands to precisely cut and shape the material, producing a finished part that matches the digital design.

What are the advantages of CNC machining?

CNC machining offers unparalleled precision and repeatability, making it a top choice for industries requiring intricate parts. Its ability to handle a variety of materials, from metals to plastics, combined with fast production times and consistent quality, makes it an essential method in modern manufacturing.

What is the difference between 3D printing and CNC machining?

3D printing is an additive manufacturing method, building parts by depositing material layer by layer. In contrast, CNC machining is a subtractive method, starting with a solid block of material and removing sections until the desired part is achieved. While 3D printing is often favored for complex geometries and rapid prototyping, CNC machining excels in durability, precision, and material versatility.

Rapid prototyping and on-demand production for a variety of industries.

01.

Automotive

02.

MedicalDevices

02.MedicalDevices

On-demand manufacturing. Rapid prototyping to mass production of medical products.

Learn more 03.

Robotics

03. Robotics

Maximize efficiency by ensuring precise, consistent, and rapid part quality.

Learn more 04.

Communication

04.Communication

Empower your team to innovate more quickly, thereby maximizing their performance.

Learn more 05.

Aerospace

05. Aerospace

Our goal is to provide efficient production and faster design-to-delivery times.

Learn more 06.

Electronics

Related Article

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

Previous image

Next image