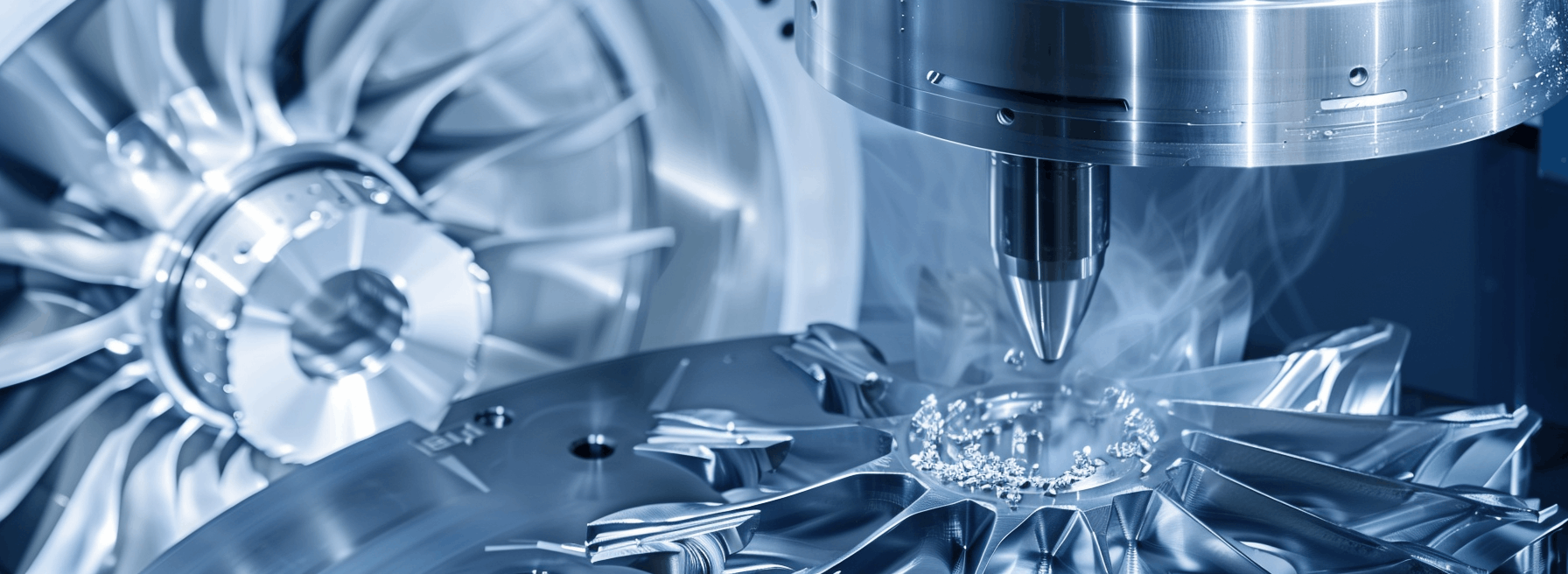

What are the requirements for machining precision parts?

Precision parts processing process has extremely strict requirements, the processing of a little carelessness will lead to workpiece error beyond the tolerance range, the need for re-processing, or announced the scrapping of blanks, greatly increasing the cost of production. Therefore, today’s LRD prototyping talk about what are the requirements for precision parts processing? Can help us improve the production efficiency.

1, the size of the processing requirements, must strictly follow the drawing of the shape and position tolerance requirements for processing. Although the enterprise processing and manufacturing of parts in practice and the size of the drawings will not be exactly the same, but the actual size of the theoretical size of the tolerance range, are qualified products, is able to use the parts.

2, CNC machining manufacturers equipment requirements, roughing and finishing should be carried out with different performance equipment. As the roughing process is to cut most of the parts of the gross bad, the workpiece in the case of large feed, cutting depth will produce a large number of internal stresses, this time it can not carry out finishing. After a certain period of time, the workpiece should be processed on a higher-precision machine tool, so that the workpiece can achieve a high degree of accuracy. United Rongda tens of millions of equipment assets to protect the customer’s products of high quality, high quality control and timely delivery!

3, precision parts processing often have surface treatment and heat treatment process, surface treatment should be placed after precision machining. And in the process of precision machining, should be considered to leave a thin layer thickness after surface treatment. Heat treatment is to improve the cutting performance of the metal, so it must be placed before machining. The above is the United Rongda precision parts processing needs to follow a few requirements.

In Shenzhen every year there will be machining machinery exhibition, each high-end precision parts processing exhibitors have their own specialization in precision parts processing capabilities – high-end ultra-precision parts processing, complex structure processing, high standard roughness machining, small batch, multi-species flexible processing, participation in product development and design capabilities and so on. Lianrongda Industry has excellent machining capabilities, is committed to building a full range of display platform, to become the industry’s leading machining manufacturers, open up the communication channels in the field of precision machining, to help improve the experience of precision parts machining, improve production and processing efficiency. We are committed to let the world see a new, high-end, strong Chinese manufacturing through their own efforts.