How can we figure out the cost of CNC machining?

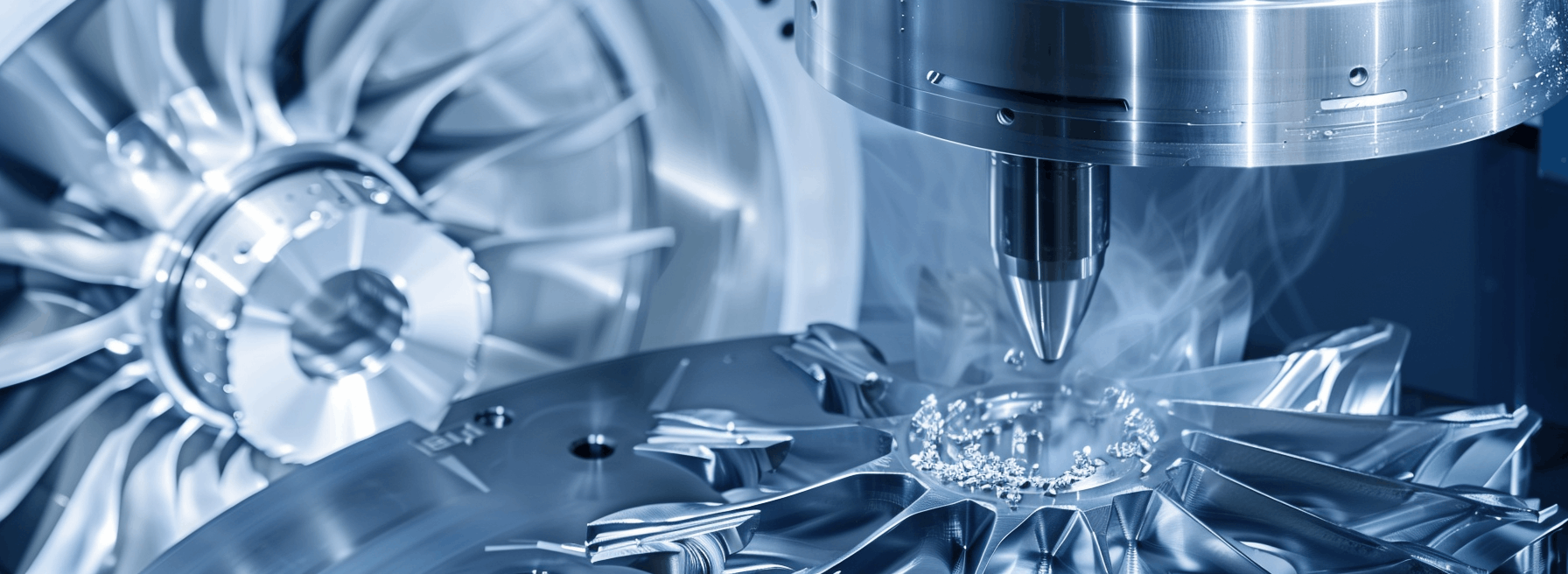

Even with all the new tech like 3D printing, CNC machining is still one of the best ways to make stuff on demand. Without it, you can’t machine metals. But with all the different things that go into it, some customers might find it tough to figure out how much CNC machining costs. Furthermore, it will provide useful advice on how to reduce these costs to fit your financial situation. Keep reading to learn more about these helpful hints.

The factors and tips on calculating the CNC machining cost

To reduce your CNC machining costs, it’s important to understand the various factors that influence them. When calculating the cost of CNC machining, machinists take the following factors into account:

1. Material costs

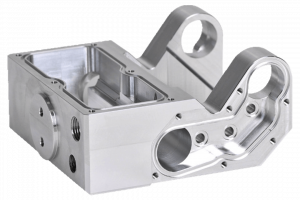

When calculating the cost of CNC machining, the first thing CNC machinists consider is material costs. Because CNC machining is a subtractive process, the finished product will always contain more material than was used in the process. Machinists purchase blocks of these materials and calculate the cost per block. Metals and plastics are the two most commonly used materials in CNC machining. Let’s take a closer look at each of them:

1.1 Metal materials

The most common metals used for CNC machining are aluminum 6061, stainless steel 303, and brass C360. Mechanics tend to prefer aluminum 6061 because it’s affordable and easy to work with. Stainless steel 303 and brass C360 are also good options, but they cost more. Our quote software can help you learn more about how material expenses are accounted for in your CNC costs.

1.2 Plastic materials

Plastics are a great choice for CNC machining because they’re cheaper and easier to work with than other materials. Even though individual blocks of POM (Delrin), ABS, and nylon 6 are pricier, their bulk costs are on par with aluminum 6061. PEEK plastics are pretty expensive, but they could be a good choice for some specific applications.

2. The cost of a CNC machine depends on the machine you use. There are two main types of CNC machining machines: three-axis and multi-axis. Three-axis machines in Europe cost about $35-$40 an hour, while multi-axis machines cost between $75-$120 an hour on the European market. You can get 3-axis machines for as little as $8-$10 and 5-axis machines for as little as $30 from Chinese companies like LRD Prototyping.

Machining costs depend on two things: the price of the machine and how many hours the machine is scheduled to run in a year (which is about 5,000 hours on average). Machinists figure out their machine shop rates by dividing the machine’s cost by the number of hours it’ll be used in a year (also called the machining cost per hour).

3. The cost of CNC machining

Because CNC machining is so automated, you don’t need to pay for a lot of staff. Basically, design and digitization account for most of the costs. There are three main labor costs associated with CNC manufacturing:

If you want to save money, you can do the CAD file development yourself. Then, a manufacturing engineer will come by to make sure your design can be repeated and suggest improvements if needed. Finally, the programmer will convert the CAD file into a CAM file so the CNC machine can understand the design.

3.2 CNC machine set up and running costs

Setting up the CNC machine for a specific task and making sure everything is done right takes a lot of time. The setup costs can vary a lot depending on how many items you’re making. Because the parts are spread out over more items, the cost per component is lower in bulk parts manufacturing.

4. Post-processing costs

After your product has been made, it has to be put together and taken to its final destination. These procedures will cost more because they require more human resources.

5. Tooling costs

If you’re using custom CNC fabrications, you might need a specific set of tools before CNC manufacturing. Even though the tool bits will be returned to the machine shop after production, you may still be responsible for some of the machine’s operating costs. When working with extremely hard raw materials, the tool used may wear out more quickly.

6. Surface finishing costs

Surface treatments on CNC machined parts can make them look better and last longer in harsh environments. Even if they’re good for you, they’ll cost more to machine.

When you’re figuring out the cost of CNC machining, it’s important to think about all of the above factors.

How to Cut CNC Machining Costs?

CNC machining can be pricey for clients who don’t produce a lot of goods. You can adjust CNC machining prices in a few different ways, depending on what you nee

1. Think about using something else that’s cheaper.

The material you choose for your product affects how much it costs to machine it using CNC. Before you choose a material for your manufacturing process, it’s important to consider how much it’ll cost to machine it. Also, it’s essential to think about how easy it is to machine the material. The time it takes to machine it affects the hourly rates for your manufacturing process, which in turn determines the cost of machining it.

2. Optimizing the Product Design

The structure of your product is taken into account when calculating CNC machining costs. The amount of time it takes to machine your part is directly proportional to its complexity. The more complex it is, the more time and money it costs. Before you send your design for a quote, ask yourself the following questions to help you reduce its complexity:

Do I really need all those features or machining options in my products? How can I make my product simpler without losing any of its functionality? Is it possible to split my design into smaller parts to make it easier to CNC manufacture and assemble? Can I modify my design to reduce the costs of setups and special tooling required? Are there any cheaper or easier-to-manufacture materials that can meet my design requirements?

If you’re looking for expert design advice, LRD Prototyping is your best bet. Our team of 250 engineers is ready to help you with any aspect of your prototyping and batch production needs. Don’t hesitate to contact us!

Cost of CNC Machining in Different Areas Chinese companies can offer lower prices while maintaining the same level of quality.

In Europe and North America, the cost of living is much higher, and CNC machining prices tend to be higher too. Prices for three-axis machines range from $35 to $40 per hour, while prices for multi-axis machines range from $75 to $120 per hour.

In Asian countries, especially in China, the cost of living is much lower, so they can offer the same high-quality service at a better price in CNC machining. Chinese manufacturers offer cost-effective CNC machining services, which is why many clients from all over the world want to work with them. LRD prototyping is a great example of a Chinese company that provides high-quality CNC machining products at a fair price.

At LRD Prototyping, we’ve got the best CNC machining methods on the market. Just get in touch and we’ll give you a free, instant quote. We’ll review your design and give you free feedback within 12 hours.

We’ve got a well-oiled manufacturing system that includes real-time progress communication and feedback. So you can count on us to manufacture and deliver your products on time and high-quality.