introductory

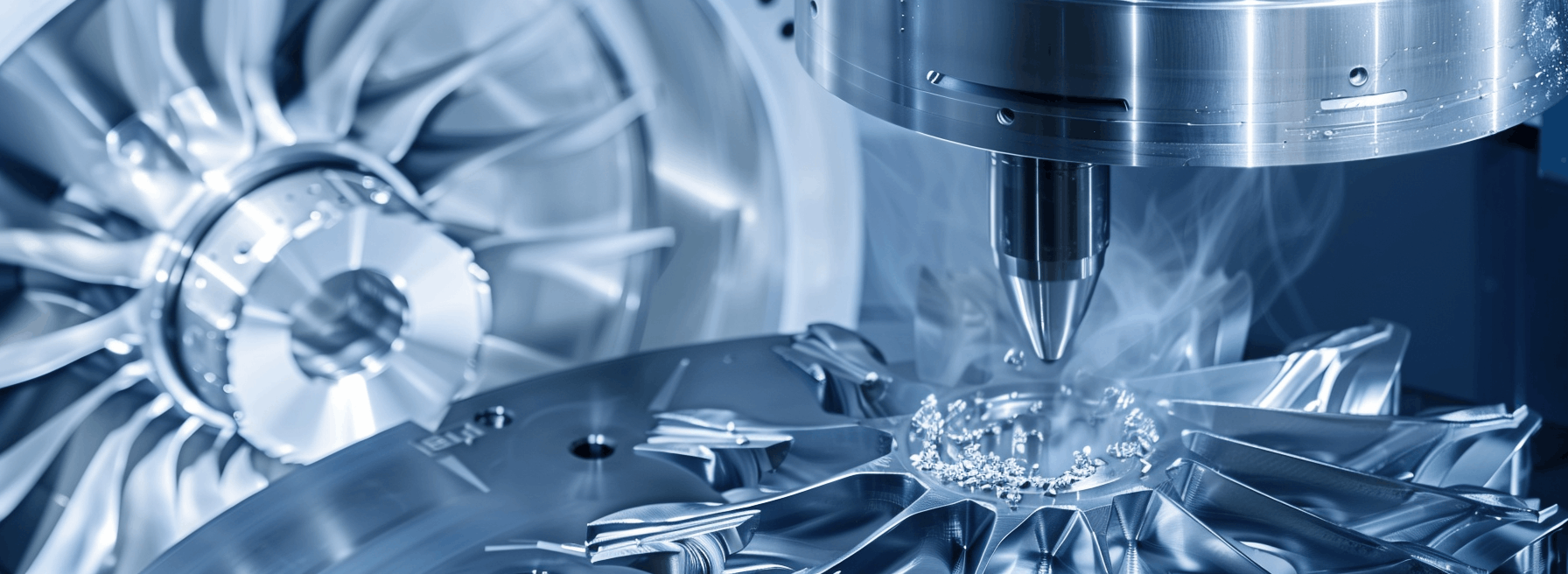

Computer Numerical Control (CNC) programming is a critical component of modern manufacturing, enabling precision and efficiency in the production of complex parts and components. Whether you’re a novice or an experienced machinist, understanding how CNC programming works is essential to optimizing your production processes. In this article, we’ll explore the basics of CNC programming, its workflow, and its applications.

What is CNC Programming?

CNC programming involves creating a set of instructions for CNC machines to follow. These machines, which include mills, lathes, routers, and grinders, use these instructions to perform precise machining operations. The primary programming language used is G-code, which tells the machine where to move, how fast to move, and what path to follow.

The CNC Programming Workflow

The CNC programming process typically involves the following steps

- Design the part

The first step in CNC programming is to design the part to be machined. This is typically done using computer-aided design (CAD) software. The CAD model serves as a blueprint, detailing the dimensions and geometry of the part.

- Converting the Design to CNC Code

Once the design is complete, it’s converted into CNC code using computer-aided manufacturing (CAM) software. CAM software translates the CAD model into G-code, which contains the instructions for the CNC machine. This step includes defining tool paths, selecting tools, and setting machining parameters such as speed and feed rate.

- Set Up the CNC Machine

Before running the CNC program, the machine must be set up. This includes installing the required tools, securing the workpiece, and configuring the machine parameters. Proper setup is critical to ensure accuracy and prevent errors during machining.

- Running the CNC program

Once the machine is set up, the CNC program can be loaded and executed. The machine reads the G-code and follows the instructions to perform the machining operations. During this process, the machine’s movements and operations are monitored to ensure that everything is running smoothly.

- Inspecting the Finished Part

After the machining process is complete, the finished part is inspected for quality and accuracy. This may include measuring dimensions, checking surface finish, and ensuring that the part meets all specifications. Any deviations are addressed, and adjustments may be made to the CNC program for future runs.

Key CNC Programming Concepts

G-Code and M-Code

G-Code is the primary language used in CNC programming. It consists of various commands that control machine movements and operations. Common G-code commands include

– G00: Fast positioning

– G01: Linear interpolation

– G02: Clockwise circular interpolation

– G03: Counterclockwise circular interpolation

M code is another set of instructions used to control auxiliary functions of the machine, such as turning the spindle on and off or changing tools. For example

– M03: Spindle on clockwise

– M05: Spindle stop

– M06: Tool change

Toolpaths

Toolpaths are the paths that the cutting tool follows to machine the part. They are defined in the CAM software and are a critical aspect of CNC programming. Efficient toolpaths minimize machining time while maintaining accuracy and quality.

Feeds and RPMs

Feeds and speeds refer to the rate at which the cutting tool moves through the material and the speed at which the spindle rotates. Selecting the appropriate feeds and speeds is critical to optimizing cutting performance, extending tool life and achieving the desired surface finish.

Applications of CNC Programming

CNC programming is used in a variety of industries, including aerospace, automotive, medical device manufacturing, and more. Its ability to produce complex and accurate parts makes it invaluable for high-precision, high-volume production.

Aerospace

In the aerospace industry, CNC programming is used to produce critical components such as engine parts, airframe structures and landing gear. The precision and reliability of CNC machining are essential to ensuring the safety and performance of aircraft.

Automotive

The automotive industry relies on CNC programming to produce engine components, transmission parts and custom body panels. CNC machines enable the production of intricate designs and complex geometries required in today’s vehicles.

Medical Devices

CNC programming is critical in the medical field for the production of surgical instruments, implants and prosthetics. The high level of precision required in medical device manufacturing is achieved through advanced CNC machining techniques.

Conclusion

CNC programming is a vital aspect of modern manufacturing, providing the precision and efficiency needed to produce complex, high-quality parts. By understanding the basics of CNC programming, from design and code conversion to machine setup and execution, manufacturers can optimize their processes and remain competitive in today’s fast-paced industrial landscape. Whether you’re new to CNC programming or looking to refine your skills, mastering these concepts will enhance your ability to create precision parts and streamline production workflows.

By following this structure and including relevant keywords such as “CNC programming,” “G-code,” “CAM software,” and “machining,” this article is optimized for search engines while providing valuable information to readers interested in CNC programming.

References

Numerical control– From Wikipedia