Previous

Next

SLA

A cornerstone in additive manufacturing, SLA 3D printing offers unparalleled precision and surface quality. This technology produces intricately detailed models and visual prototypes, ensuring high resolution and smooth surfaces ideal for complex geometries.

SLS

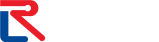

This versatile method is renowned for its strength and durability. SLS 3D printing is ideal for functional parts, as it creates complex, high-quality prints without the need for support structures, enabling more design freedom.

SLM

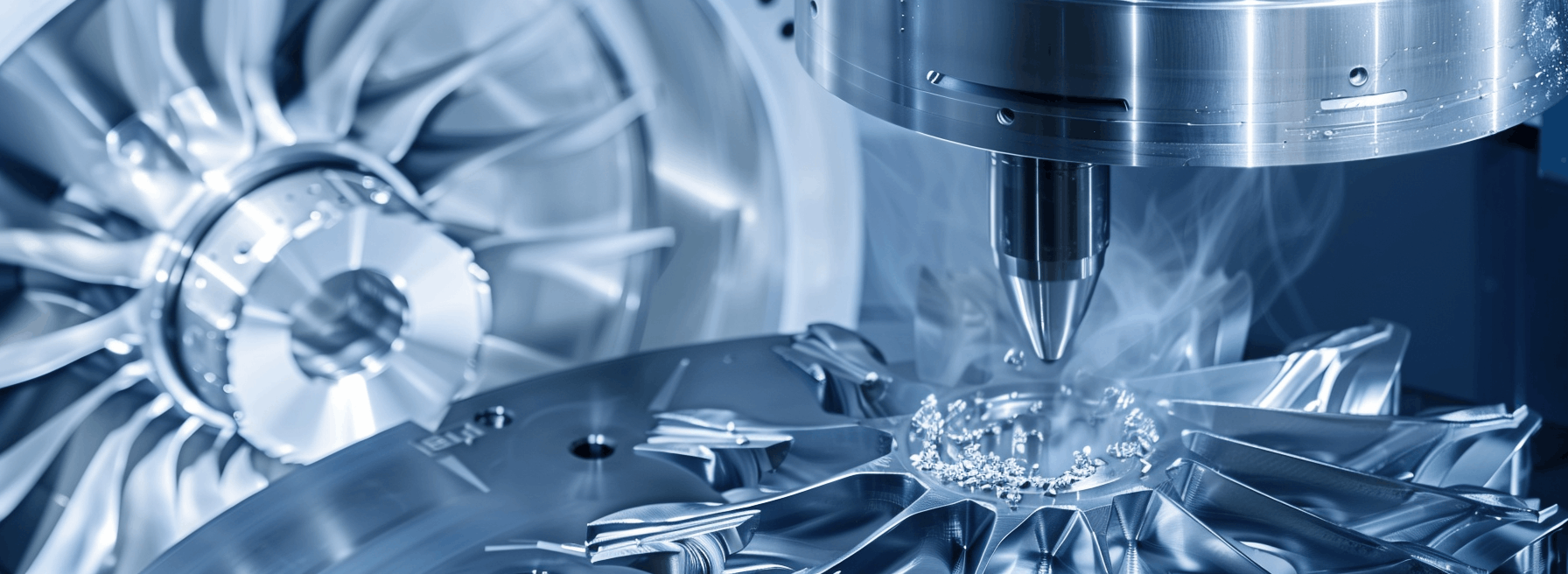

SLM 3D printing is a manufacturing process that fuses metal powders into solid parts. Ideal for the aerospace and automotive industries, this technology offers strong, complex geometries, ensuring high-performance and durable components with intricate designs.

MJP

The latest technology for producing high-speed, accurate-to-CAD precision parts and prototypes is Multi-Jet Printing (MJP) 3D printing services from 3D Systems. MJP is capable of printing in Ultra High Definition mode, enabling the printing of even smaller features, down to 300 microns or finer.

FDM

Fused Deposition Modelling (FDM) is the most commonly associated with 3D printing. It is one of the more common 3D printing technologies and also one of the most versatile, but also most misunderstood. Many people assume that FDM is only used for very basic prototypes and models. However, FDM parts are also used in very intense aerospace and automotive applications as well as a world of other uses.

MJF

A revolutionary technology offers high-speed production and consistent quality, making it ideal for functional parts. HP MJF 3D printing ensures strong, detailed, and dimensionally accurate prints with excellent mechanical properties, making it an excellent choice for functional parts.

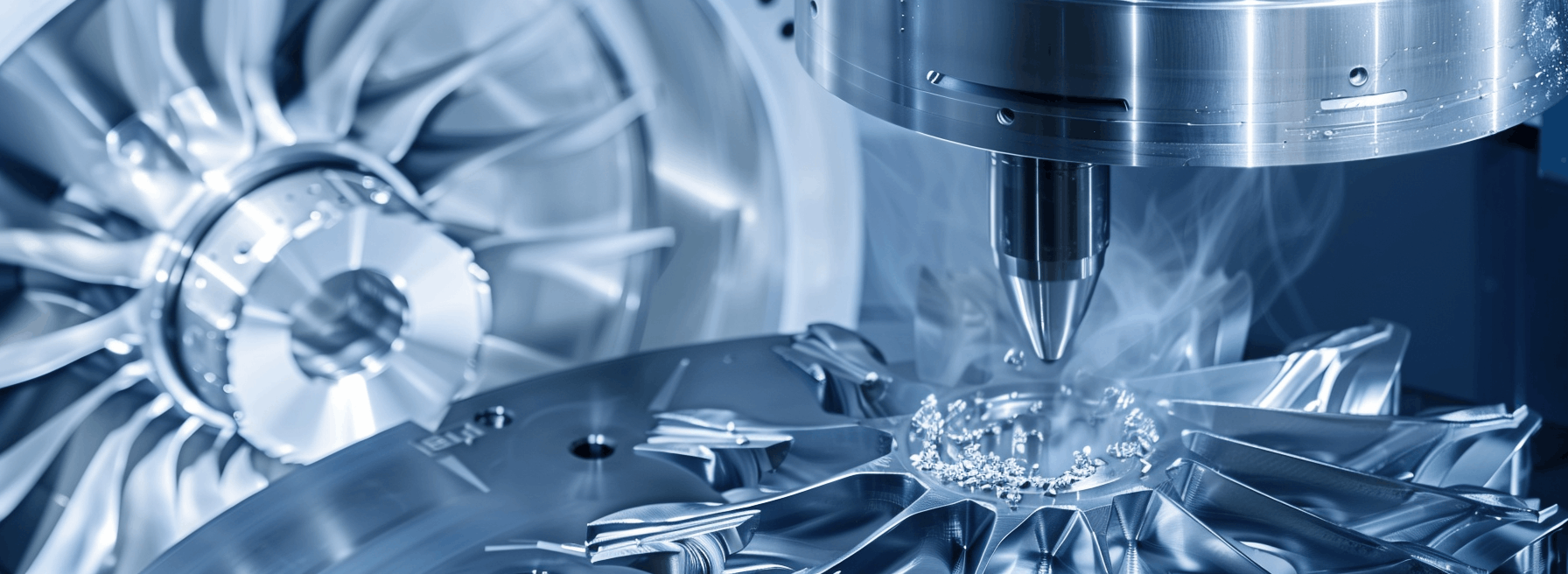

Our Services

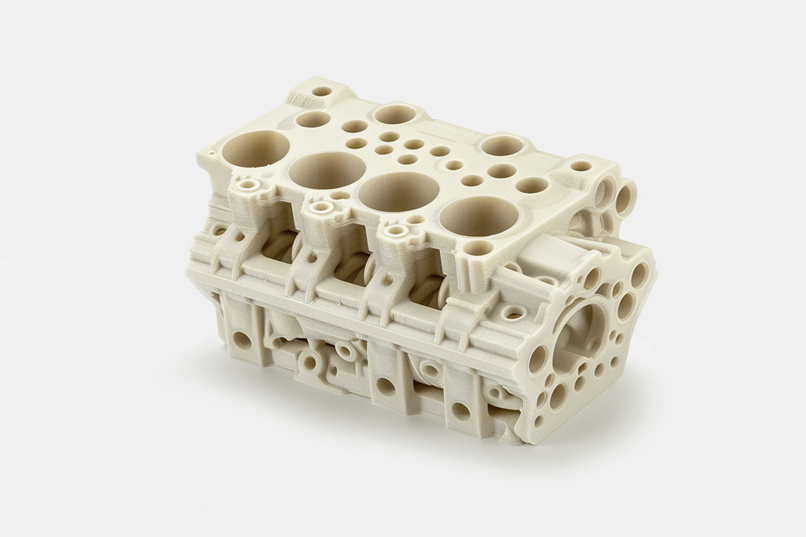

Our Custom 3D Printing Services

LRD Prototyping offers a comprehensive range of in-house custom metal and plastic 3D printing services, enabling us to deliver printed parts in all forms, complexities, and sizes, and fitted for different functions and applications.

Need help?

Call us for more information or business inquiry.

+86 18923709879

Wind Farms in Wales

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Wind energy at Monaco

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Jakarta Airport International

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Custom 3D Printing Parts

Previous image

Next image

LRD 3D Printing Capabilities

| SLA | SLS | DMLS | MJP | FDM | MJF | |

| Build size | 800 * 800 * 550mm | 400 * 400 * 450mm | 280 * 280 * 280mm | 300 * 180 * 150mm | 750 * 750 * 750mm | 380 * 284 * 380mm |

| Lead time from | 2 days | 3 days | 3 days | 2 days | 2 days | 4 days |

| Resolution | ± 0.2mm | ± 0.2mm | ± 0.3mm | ± 0.1″mm | ± 0.3mm | ± 0.3mm |

Prototyping applications | Highly detailed visual prototypes. | Functional prototypes for testing or usability trials. | Metal prototypes with complex geometries. | Fine-detailed high-resolution prototypes. | Proof-of-concept prototypes from a wide range of materials. | Functional and high-fidelity prototypes. |

End-use applications | Small aesthetic, non-functional end parts. | Low-volume functional plastic parts. | Low-volume fully functional complex metal components. | Small batch of high-resolution end-use parts with high fidelity. | Non-visual end parts, such as jigs and fixtures. | Low-volume functional parts. |

Start production today.

Make on-demand manufacturing easier and faster.

3D Printing Tolerance

In the absence of specific shape and position dimensions not noted, we adhere to the GB 1804-2000 L level for implementation and testing. Please refer to the following table for further details.

| Basic Length | |

| Straightness and Flatness | 0.1 to 1.6 mm |

| Verticality Tolerance | 0.5 to 2 mm |

| The Degree of Symmetry | 0.6 to 2 mm |

| Circular Runout Tolerance | 0.5 mm |

Materials for 3D Printing

| Mateirals | Description | Technology | Color | Types |

ABS and Resins | ABS is a leading choice for 3D printing due to its strength, durability, and higher temperature resistance. Ideal for functional prototypes and complex designs, ABS ensures reliable performance and an impressive finish. | SLA | White, Beige, Black, Red, Semi-transparent | Our product range includes ABS photosensitive resin, high temperature resistant 70°C photosensitive resin, black toughness 70°C heat-resistant photosensitive resin, semi-transparent photosensitive resin, and white tough resin. |

PA (Nylon) | Nylon is an excellent choice for small quantities of prototypes and durable end-use products. Its exceptional strength, flexibility, and abrasion resistance ensure high-quality, long-lasting printing. | MJF, SLS | Original color, gray-black, black painted | HP Nylon |

Aluminum | Aluminum metal 3D printing offers a unique blend of lightness and strength with exceptional thermal conductivity and resistance to corrosion, making it an optimal choice for high-precision, durable prints. | SLM | Silvery Gray | ALSI10MG Aluminum Alloy |

Stainless Steel | Stainless steel is the ideal material for industrial 3D applications due to its unparalleled strength, resistance to corrosion and heat, and durability. It ensures the production of high-quality, precise parts with excellent mechanical properties. | SLM | Gray-black | 316L Stainless Steel |

3D Printing FAQ

Yes, at LRD Prototyping, we offer both selective laser melting (SLM) and direct metal laser sintering (DMLS) services. Our 3D printing capabilities extend to a wide range of metal alloys, including aluminum, titanium, stainless steel, copper, nickel-base superalloy, and bronze.

The cost of 3D printing can vary significantly, from a few dollars to hundreds or even thousands of dollars. The price depends on several factors, including the material, printer, printing time, model complexity, and cost of labor. For instance, metal 3D printing will typically cost more due to the higher material and machinery cost and the longer labor-intensive post-processing work involved.

In manufacturing, the quality of your last order determines your reputation. We take quality seriously and ensure that our 3D printed parts meet the highest standards. Once completed, your parts are transferred to our quality control department for inspection. We provide a comprehensive, standardized inspection report with every order to ensure that our quality metrics are being met.

Furthermore, we are able to provide multiple certifications upon request, including ISO 9001, ISO 14001, ISO 27001, and IATF 16949.

Industrial 3D printing is revolutionizing the manufacturing process. It offers a new way for individuals to design and create products in ways that were previously not possible. Instead of being constrained by traditional manufacturing methods, 3D printing enables designers to create intricate and complex shapes that were not feasible before. This is a significant advantage for rapidly developing new ideas and bringing them to market more efficiently.

One of the most appealing aspects of 3D printing is its ability to facilitate the creation of products that are precisely tailored to specific needs. This personalization can be achieved without incurring significant costs or delays. Additionally, 3D printing enables the production of only the necessary quantities, reducing waste and optimizing resource utilization.

Another noteworthy aspect of 3D printing is its compatibility with a diverse range of materials, including plastics and metals. This versatility positions 3D printing as a valuable tool across diverse industries, contributing to the manufacturing of components for airplanes, cars, medical devices, and more.

In essence, 3D printing is revolutionizing the manufacturing process by making things quicker, more customized, and better suited to what we need. It’s a whole new way of making things!

Rapid prototyping and on-demand production for a variety of industries.

01.

Automotive

02.

MedicalDevices

02.MedicalDevices

On-demand manufacturing. Rapid prototyping to mass production of medical products.

Learn more 03.

Robotics

03. Robotics

Maximize efficiency by ensuring precise, consistent, and rapid part quality.

Learn more 04.

Communication

04.Communication

Empower your team to innovate more quickly, thereby maximizing their performance.

Learn more 05.

Aerospace

05. Aerospace

Our goal is to provide efficient production and faster design-to-delivery times.

Learn more 06.

Electronics

Related Article

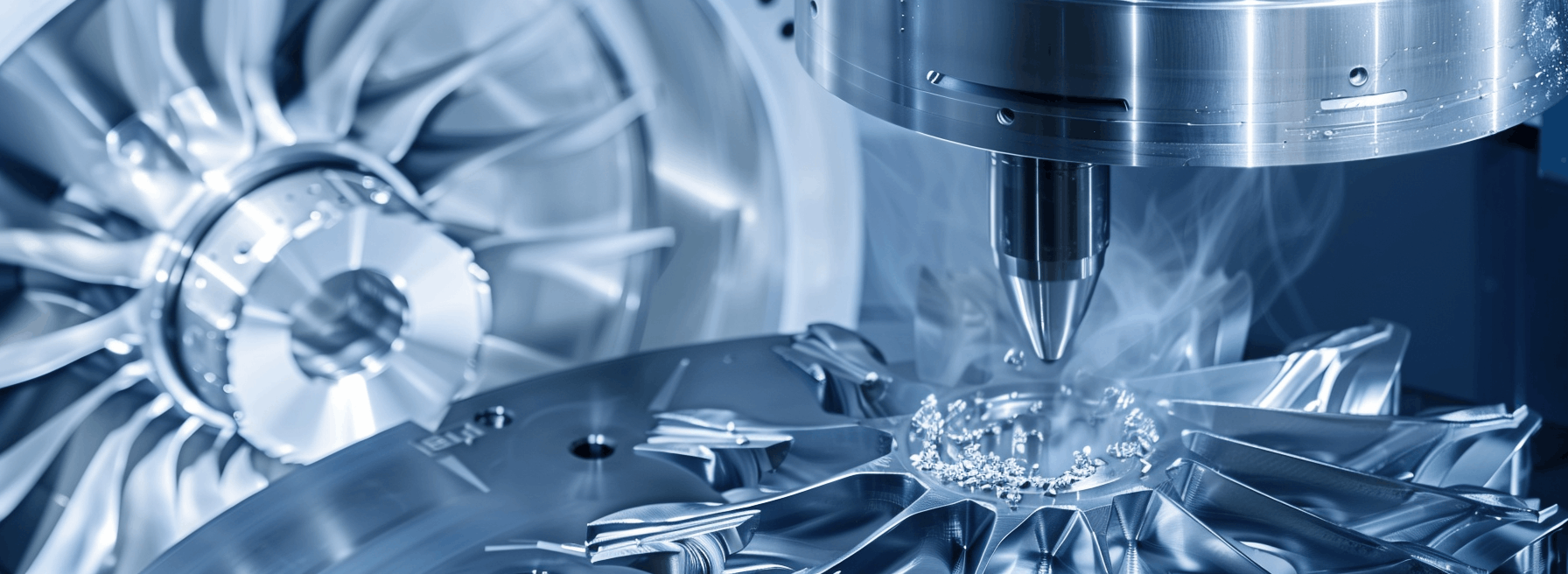

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

Previous image

Next image