Create. Enhance. and Sustain.

Primis non dignissim hac ac iaculis eget vivamus potenti volutpat lorem odio porta curae mattis

Previous

Next

Rapid prototyping

ISO accredited & QC checks

15+Yaers experience

NDA is available

FREE Instant quote

Who we are

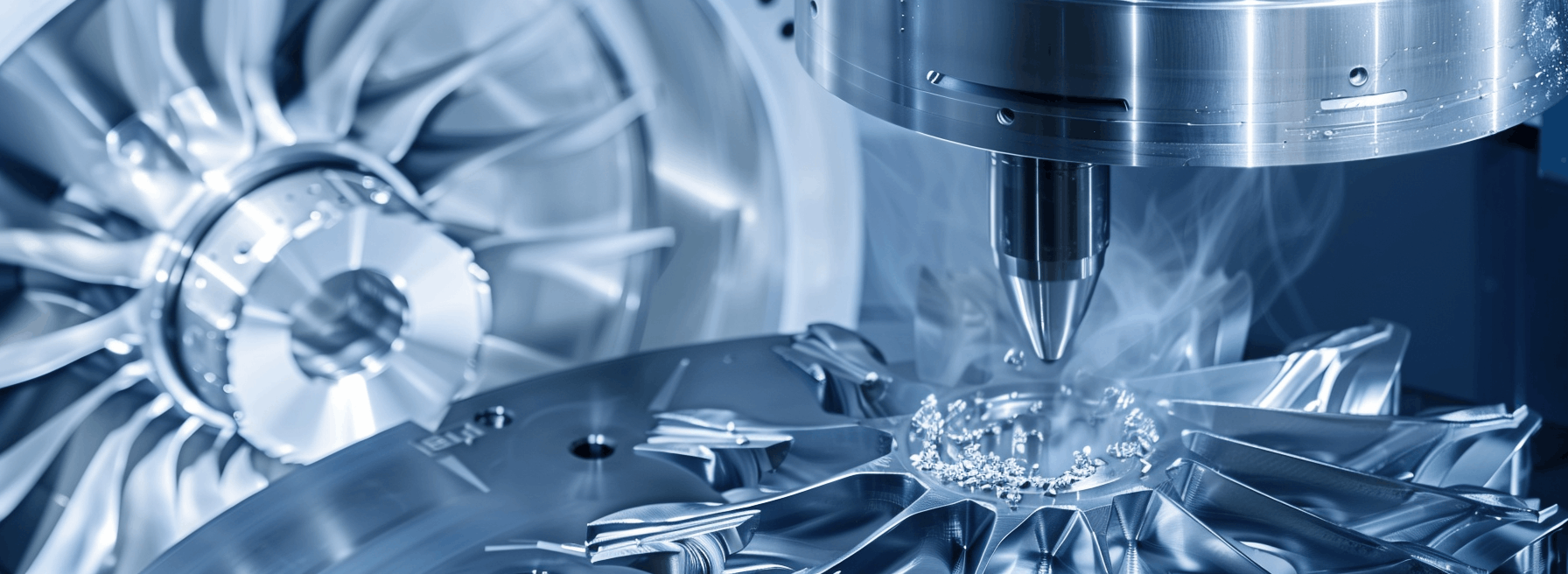

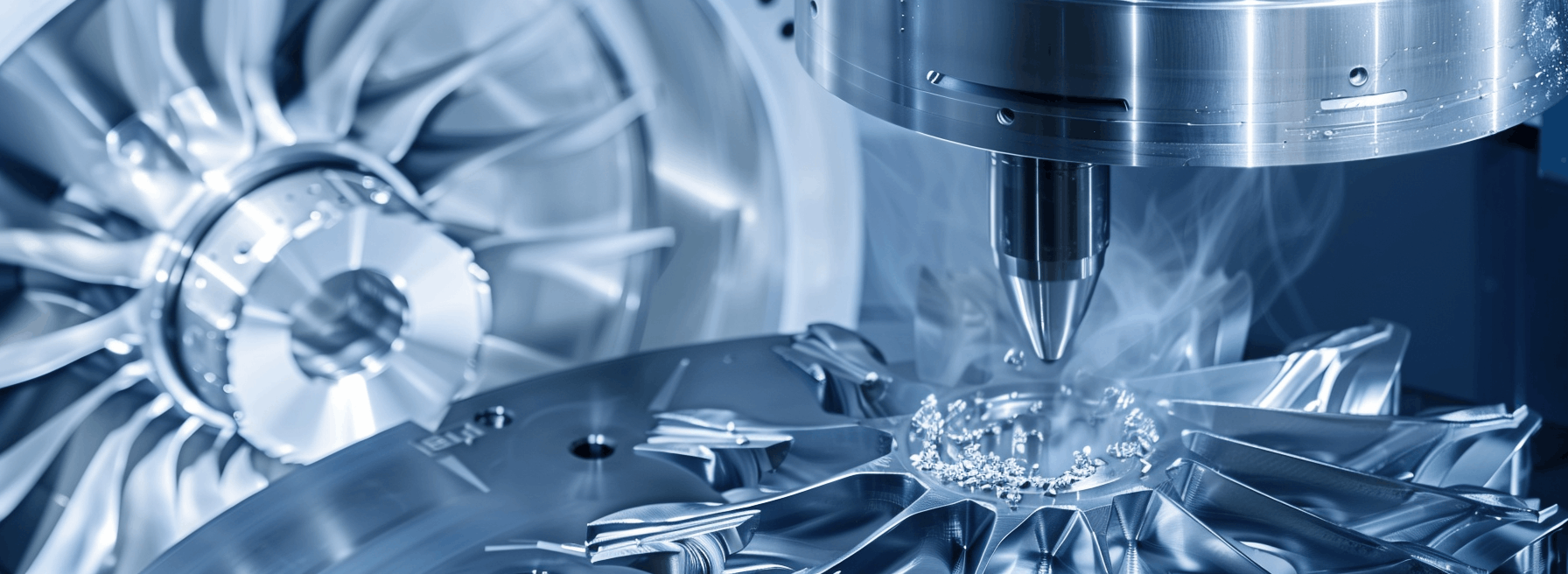

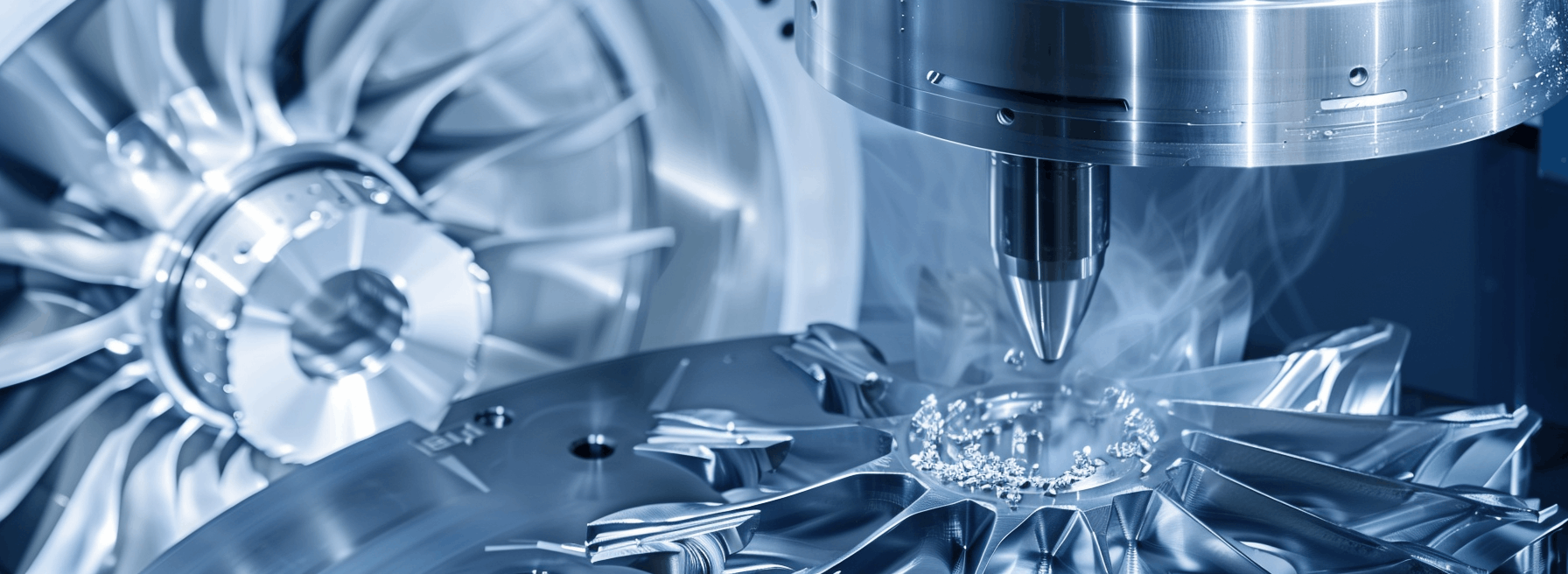

LRD Prototypes, Custom Prototype Manufacturing

LRD Prototypes is a leading provider of rapid prototype manufacturing services to customers worldwide. Our comprehensive range of 3D printing, CNC and injection molding services includes everything from prototype to production manufacturing solutions.

- Rapid CNC Machining Service

- Rapid Injection Molding Service

- Sheet Metal Fabrication Service

- 3D Printing Service

Tips

LRD prototyping minimum order quantity (MOQ) begins at 1 unit for prototypes and typically reaches 100,000 parts (plastic, metal, composites). This range is what we consider low-volume manufacturing.

Rapid prototyping and on-demand production for a variety of industries.

01.

Automotive

02.

MedicalDevices

02.MedicalDevices

On-demand manufacturing. Rapid prototyping to mass production of medical products.

Learn more 03.

Robotics

03. Robotics

Maximize efficiency by ensuring precise, consistent, and rapid part quality.

Learn more 04.

Communication

04.Communication

Empower your team to innovate more quickly, thereby maximizing their performance.

Learn more 05.

Aerospace

05. Aerospace

Our goal is to provide efficient production and faster design-to-delivery times.

Learn more 06.

Electronics

LRD Manufacturing Capabilities

Previous image

Next image

How We works

LRD Prototyping have streamlined the process for fulfilling your custom parts needs into four simple steps.

Upload Your File

LRD prototyping engineers will review your project and create detailed flowcharts and cost estimates.

Manufacturing begins

All in-house processes are conducted at our manufacturing plant in China.

Quality control

ISO and IATF accredited. All in-process and 100% factory quality control checks are conducted.

Have Parts Shipped To You

All outgoing quality control checks have been completed. The parts will be shipped via DHL Express or a similar service.

Why Choose US

LRD Prototyping offers high-quality precision machining with a wide range of manufacturing capabilities. We help manufacture products with complex geometries and high aesthetic demands. Our experts and advanced technologies allow us to provide many on-demand manufacturing services.

CNC Machining Services

CNC milling (3, 4 and 5 axes) and CNC turning services with tight tolerances.

Sheet Metal Work

Laser cutting, punching, welding and Stamping Sheet Metal

Rapid Injection Moulding

Rapid tooling and plastic injection moulding services. From as fast as 2 weeks.

3D Printing Services

SLA,SLS,DMLS, MJP FDMSLM, MJF solutions.

Vacuum Casting

Produce plastic and rubber parts without the costor lead time required for production tooling

Die Casting

Produce from 10 to 100,000+ productionquality metal components.

Metal Injection Moulding

LRD controls MIM tolerances to ±0.05mm or better.

Surface Finishing

We can finish metal, composites, and plastic parts so you can bring your prototype or part to life.

Assembly

Our custom assembly services ensure quality, save time, and meet project specifications.

What Our Clients Say

The service at LRD Prototyping is exceptional. Steven has been extremely helpful and understanding. The service and product are exactly what we requested and perform extremely well. Especially considering the small details we requested.

I'm happy with this order. The quality is as promised, and the delivery was fast. The service was great. I want to thank Zhou from the sales team and the engineer for their help.

Dear Steven,Thank you for your assistance in obtaining the product. It has been delivered and is in excellent condition.We appreciate your prompt assistance in this matter and look forward to placing future orders.Best regards

Related Article

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

Previous image

Next image